An established and efficient method of removing impurities and creating a pure product is by using activated carbon. Our carbon-based products can also be used to recycle resources for future use and prevent damage to industrial machinery.

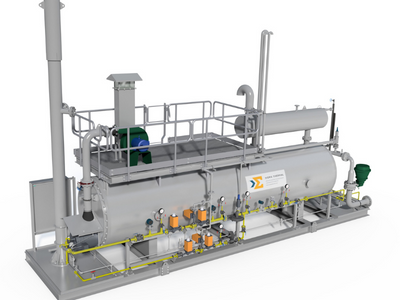

Amine and Glycol Recovery

Activated carbon can significantly extend the service life of the amine by treating a side stream of recirculating amine liquor to remove or reduce H2S/CO2 and other degradation compounds from natural gas. By controlling the amount of Heat Stable Salts (HSS) produced during the stripping of the rich amine solution, this capability safeguards other equipment in the circuit.

Similarly, purifying the glycol used in gas dehydration processes guarantees top performance and lowers the chance of secondary raffinate contamination.

Activated carbon will:

- Reduce circulating solvent/absorbent inventory deterioration to a minimum

- Eliminate dangerous impurities from the end product

- Safeguard process equipment

- Maximize the use of absorbents and processing chemicals

- Improve the performance of the process equipment

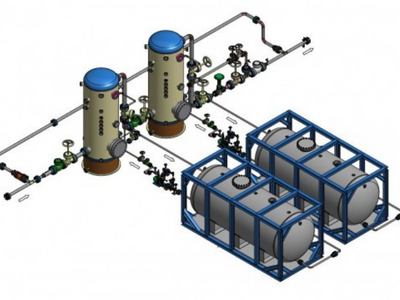

Condensate Treatment

Reusing condensate steam as boiler feedwater is a common practice in the petrochemical and power generation industries. This method boosts plant profitability and provides a ready supply of heated water. However, recycled condensate, which includes organics (such as oil) and solids like metallics in ionic form, accumulates contamination from the system. Systems that purify recycled water using activated carbon and ion exchange resin are frequently used to manage these undesirable condensate constituents. In these situations, it is crucial to make sure that each step of the mineral release and slip treatment are carefully managed by the appropriate media selection and sizing of equipment. The boiler and turbines will continue to effectively run due to this process.

HPNA Removal

In the hydrocracking reactors, certain compounds known as heavy polynuclear aromatics (HPNA) are created because of the condensation of aromatics and the dehydrogenation of polynaphthenes. Once this has happened, HPNAs become extremely difficult to remove and begin accumulating, leading to critical heat exchanger fouling and catalyst deactivation. These compounds are regarded as refractory in the hydrocracking procedure and exhibit high conversion resistance in a hydrocracking reaction zone. This must be avoided because it lowers production quality so the best way to get rid of these unwanted elements is with our activated carbon products.

Mercaptan Removal and Fuel Sweetening

Mercaptans are organic compounds of hydrocarbons and sulfur that have a distinctive bad odor as well as corrosive properties in pipelines. As a result, mercaptans in high concentrations in natural gas must be removed to provide a suitable feedstock or end-product. To separate the mercaptans from natural gas in the sweetening plant, the mercaptans normally undergo the process of oxidization. This is a catalytic process that frequently involves activated carbons.