Overview: Modular Container Biofilters

Presenting our modular container biofilters systems: self-contained units engineered to handle large waste air streams across diverse municipal and industrial settings. Their adaptable design accommodates increased airflow rates, ensuring seamless integration into your operation. These turn-key solutions facilitate quick one-day installations.

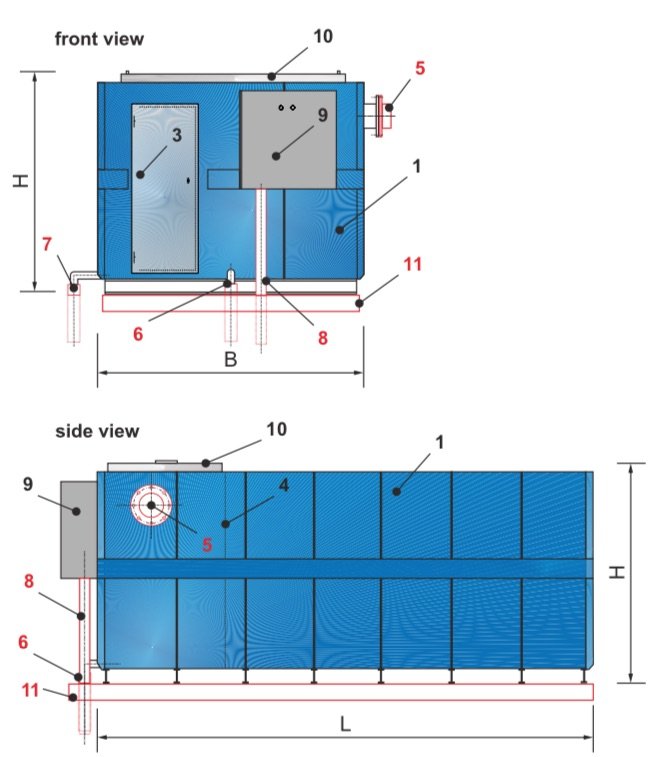

The Continental Carbon Group Modular Container Biofilters Systems comprises one to four double-walled filter containers alongside an integrated technical container housing the fan, air scrubber, and irrigation system controls.

Operating automatically with minimal maintenance, each MCBF Biofilter is customized to meet your exact specifications. Applications span wastewater treatment plants, headworks, biosolids and septic receiving areas, larger pump stations, composting facilities, the food industry, landfills, the chemical industry, and beyond.

Streamlined Odor Control Solutions: Container Biofilter (Compact Module)

Every Continental Carbon Group MCBF Biofilter container features a double-walled construction, comprising outer steel walls and inner walls crafted from high-density polyethylene, ensuring contact with the contaminated air stream. Inner containers are equipped with baffles to prevent wall channelling effects.

Pre-filled with our proprietary Continental Carbon Group bps BT-100 Biofilter Material, derived from specially prepared pine root fibers, our biofilters boast low back pressure and long-term stability, translating to reduced energy costs over time. This environmentally friendly material lasts 3 to 7 years, requiring no additional nutrient feed system and composting easily after use.

Equipped with an accessible technical container housing the air humidifier, fan with VFD, heater, irrigation controls, and internal ducting, our biofilters not only shield mechanical parts from the elements but also serve as sound enclosures for the fan, crucial for installations in residential neighborhoods.

Prior to entering the biofilter media bed via the air distributor, waste air undergoes humidification and conditioning in the air scrubber. Water in the humidifier is recirculated by a circulation pump, with electronic level sensors ensuring automatic refilling. The total back pressure of the complete plant (scrubber AND biofilter) will not exceed 1,000 Pa.