BTD Series

The Continental Carbon Group Bubble Tight Isolation Damper (BTD) is designed for isolation of critical filter trains or environmental emission control systems during change-out, decontamination, shutdown, and/or testing services without disabling the entire system or risking air emissions that could affect compliance. Damper operation can be manual or electric. Dampers can be manufactured out of 304 stainless steel. Other materials available upon request.

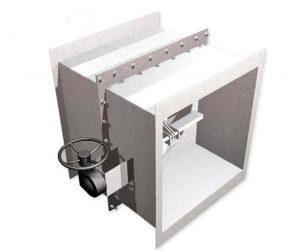

Square BTD

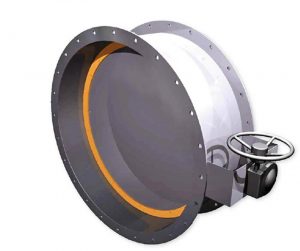

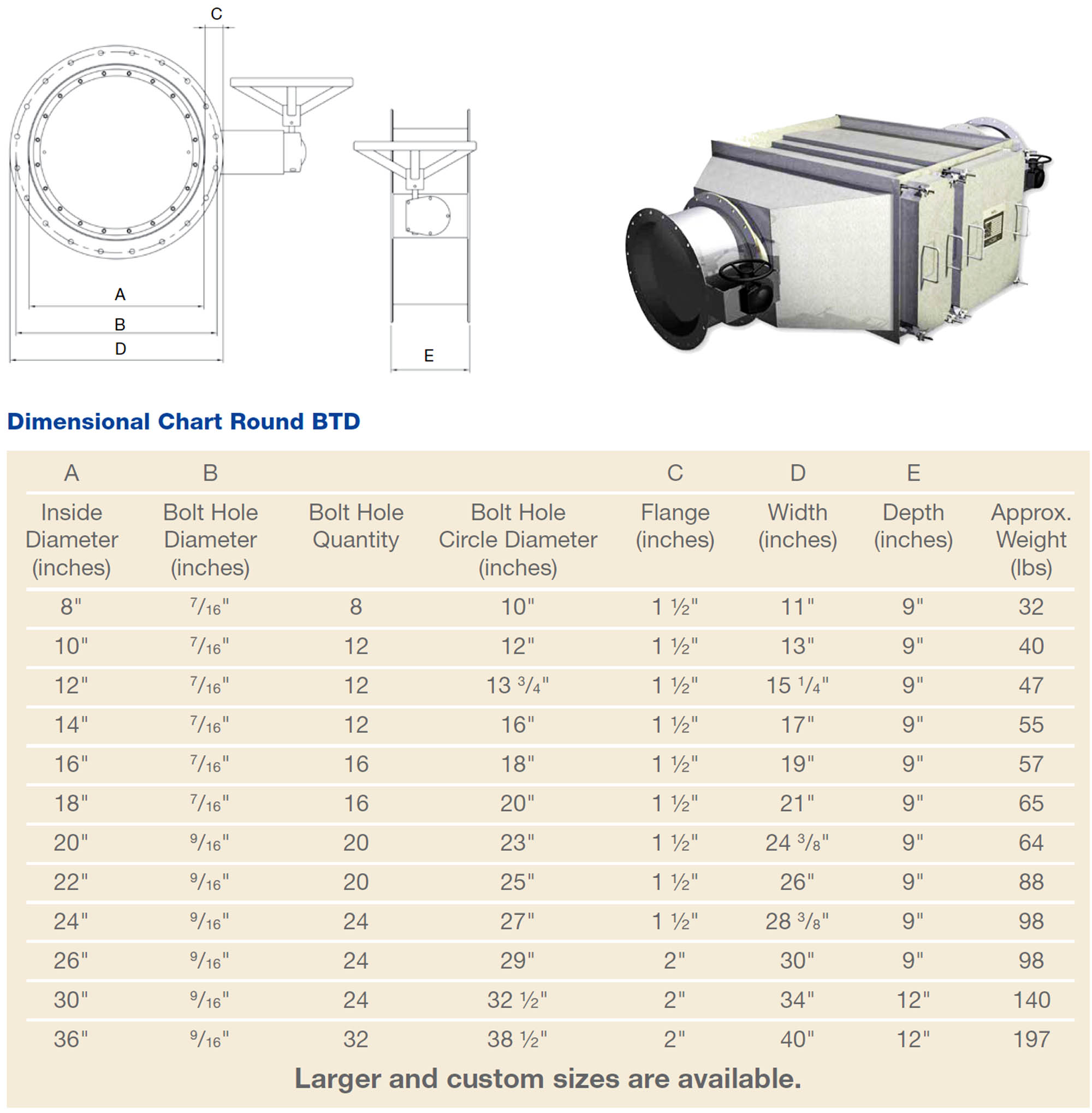

Round BTD

BTDs can be used in:

- Room isolation

- Containment housings

- Dust collectors

- HVAC

- Building isolation systems

The damper is also available with a bubble tight certification per ANSI test method N510-1980. In a hazardous atmosphere, the Series BTD Isolation Damper enables the system to be isolated for decontamination, filter change-out or to allow scan testing by an auxiliary air supply system. In a nonhazardous atmosphere, it prevents particulates or vapor phase chemical contaminates from reaching the atmosphere or other equipment and processes to which the system being isolated may be connected.

Design Specifications

BTD Isolation Dampers are available for either round or square duct in temperatures ranging from -50Æ F to 375Æ F. The damper is designed with a single blade mounted to a shaft with a fabricated flange frame. The damper contains a full circumference silicone blade seal that is retained by a steel clamp ring fastened by hex nuts. Manual or electric actuators can be supplied as required.

The blade seal is field adjustable and replaceable. The shaft is supported in self-lubricating TFE lined filament wound bearings mounted external to the damper frame with O-ring shaft seals.

Standard sizes range from 8″ to 36″ round and custom sizes are also available.

Square BTD

The square BTD attaches directly to the containment housing, which eliminates the need for transitions between the housing and damper as is required when using the round BTD. Damper housing is 24″ square duct with a flange total width of 27″; a total flange height of 30″; and adds 26 ó” to the length of the containment unit. Damper operation can be manual, electric, or pneumatic.

Continental Carbon Group is constantly striving to improve its products and capabilities and to provide the best product to it customers. Continental Carbon Group may from time to time develop product improvements or alterations (including, without limitation, revisions to product specifications), and may implement such Product Improvements without notice to the Buyer.

Making Air Safer and Cleaner

SAFETY MESSAGE

Wet activated carbon removes oxygen from air, causing a severe hazard to workers inside carbon vessels. Confined space/low oxygen procedures should be put in place before any entry is made. Such procedures should comply with all applicable local, state and federal guidelines.