DESCRIPTION

The Continental Carbon Group Front and Side Access assemblies are commercial and industrial duty activated carbon filters designed to purify air streams contaminated with odors and irritants associated with new construction and furnishings, manufacturing processes, and other air pollutants. In most cases the purified air can be recirculated, resulting in reduced make-up air requirements and energy savings.

HOW IT WORKS

Granulated activated carbon (GAC) is like a molecular magnet. GAC is microstructured of millions of tiny pores and interconnecting capillary passages that represent a surface area of millions of square feet per pound of carbon. As contaminated air passes through the carbon bed, the vaporous contaminates disperse throughout and are adsorbed on this vast surface. To promote retention of certain gases not readily adsorbed on standard activated carbon, specially impregnated activated carbons are utilized. Impregnated activated carbons combine adsorption with chemical reactions to permanently remove these contaminants from the air stream.

EQUIPMENT SELECTION

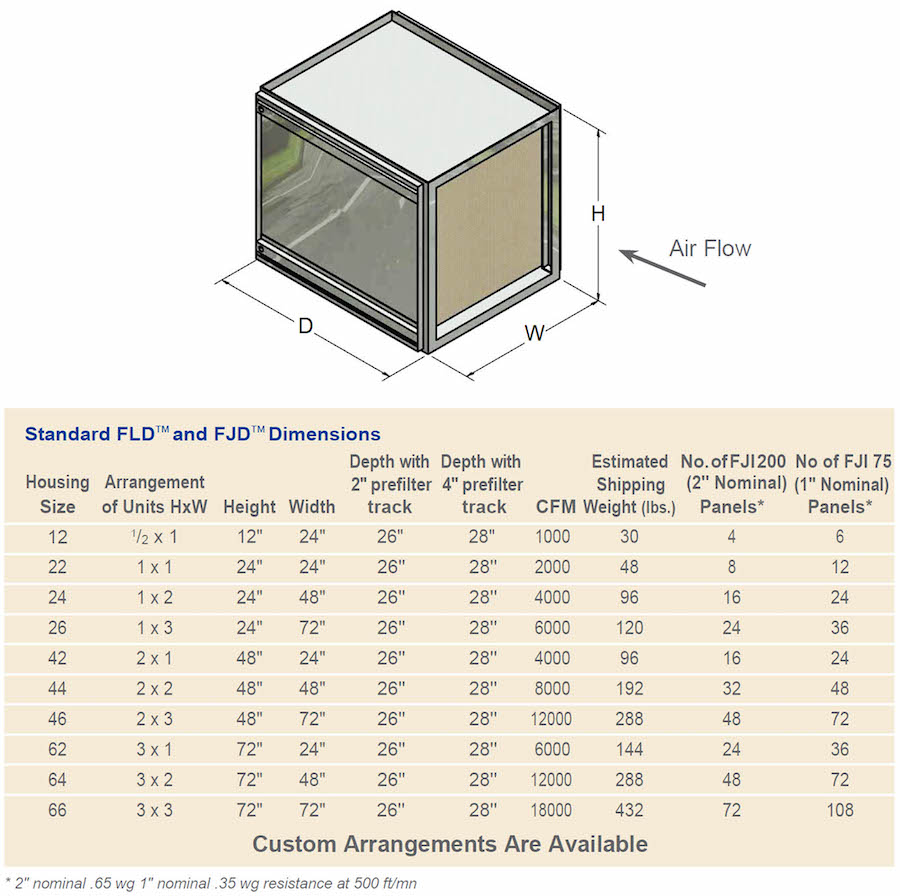

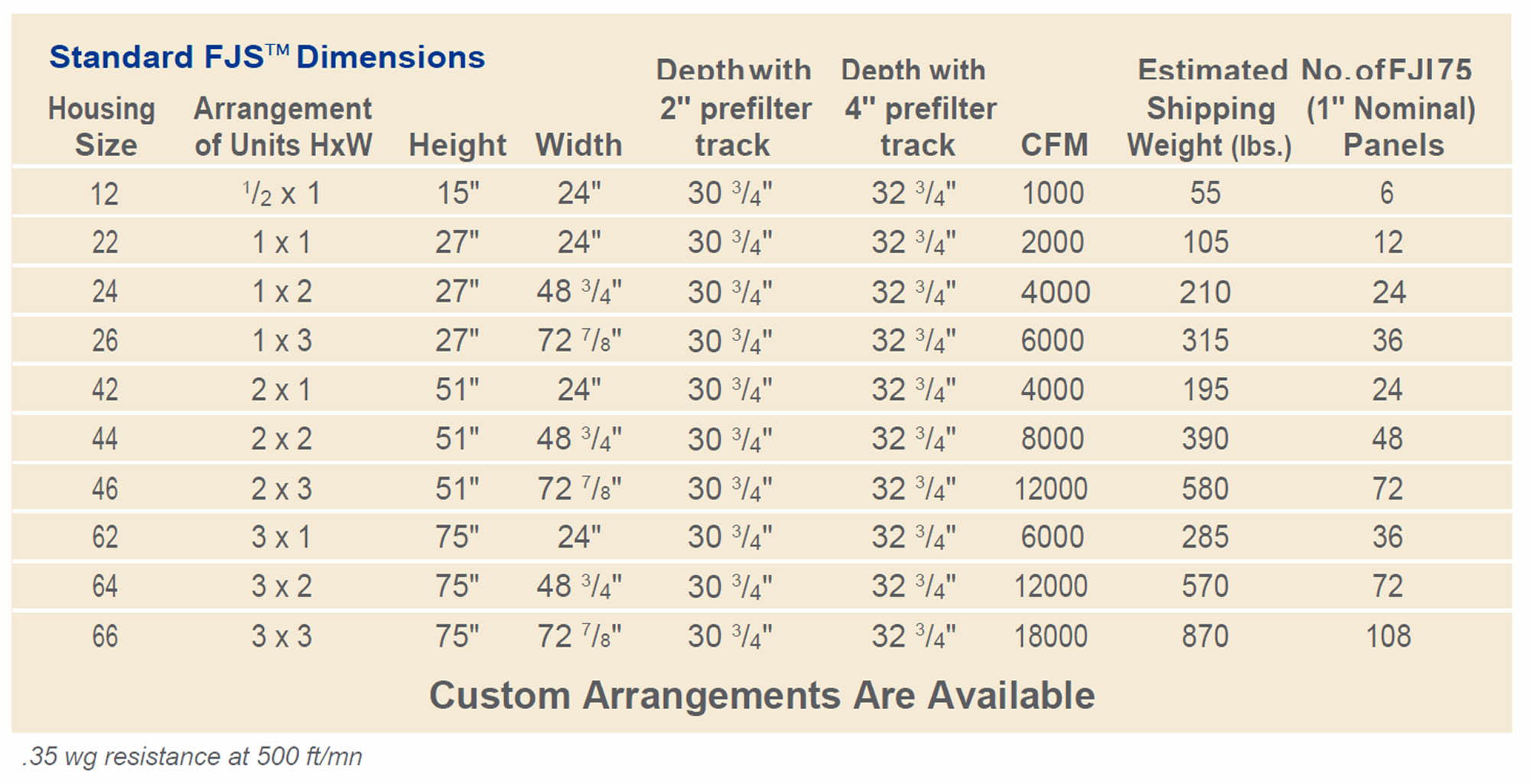

The series FLS™ or FJS™ (side) and FLD™ or FJD™ (front) adsorber assemblies are designed for commercial duty operation. The “L” units use 2”-thick panels, while the “J” units use 1″-thick panels. Consider these housings for the following:

- Reduce make-up air costs by removing odors and recirculating purified air.

- Purify and recirculate room air where make-up air is not available.

- Purify contaminated make-up air.

- Purify contaminated exhaust air.

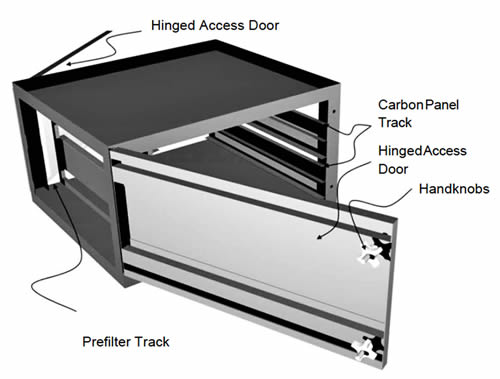

SIDE ACCESS HOUSING FEATURES

- Durable all-welded 16-gauge electro-galvanized steel housing. 14-gauge continuous weld option. Painted carbon steel or 304 stainless steel optional.

- 2″, 4″, 6″ pre-and post-filter tracks available.

- Quick -entry, hinged side access doors on each side of housing to simplify filter installation and change-out. Optional bolted doors are available for space-limited installations.

- Foam gaskets on doors to prevent leakage.

- Completely factory assembled and self- supporting.

- Modularly designed with nominal 500 fpm face velocity compatible with most air handling and particulate filtration equipment.

- Optional match-up transitions for unique applications.

- Full-size, easy-to-handle nominal panels to expedite panel change-out and minimize pressure drop (for panel sizes see page 4).

- Half size available to accommodate range of housing widths.

- Weather cap for outside installations optional.

- Can be provided with fan and particulate filters as a skid-mounted system.

FRONT ACCESS HOUSING FEATURES

- Durable all-welded 16-gauge electro- galvanized steel housing. 14-gauge continuous weld option. Painted carbon steel or 304 stainless steel optional.

Completely factory assembled and self-supporting. - Modularly designed with nominal 500 fpm face velocity compatible with most air handling and particulate filtration equipment.

- Optional match-up transitions for unique applications.

- Full-size easy-to-handle nominal panels to expedite panel change-out and minimize pressure drop (for panel sizes see page 4).

- Half -size available to accommodate range of housing widths.

- Weather cap for outside installations optional.

- Can be provided with fan and particulate filters as a skid-mounted system.

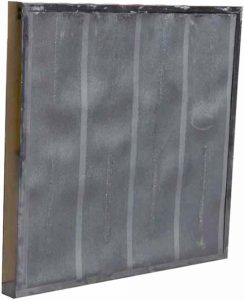

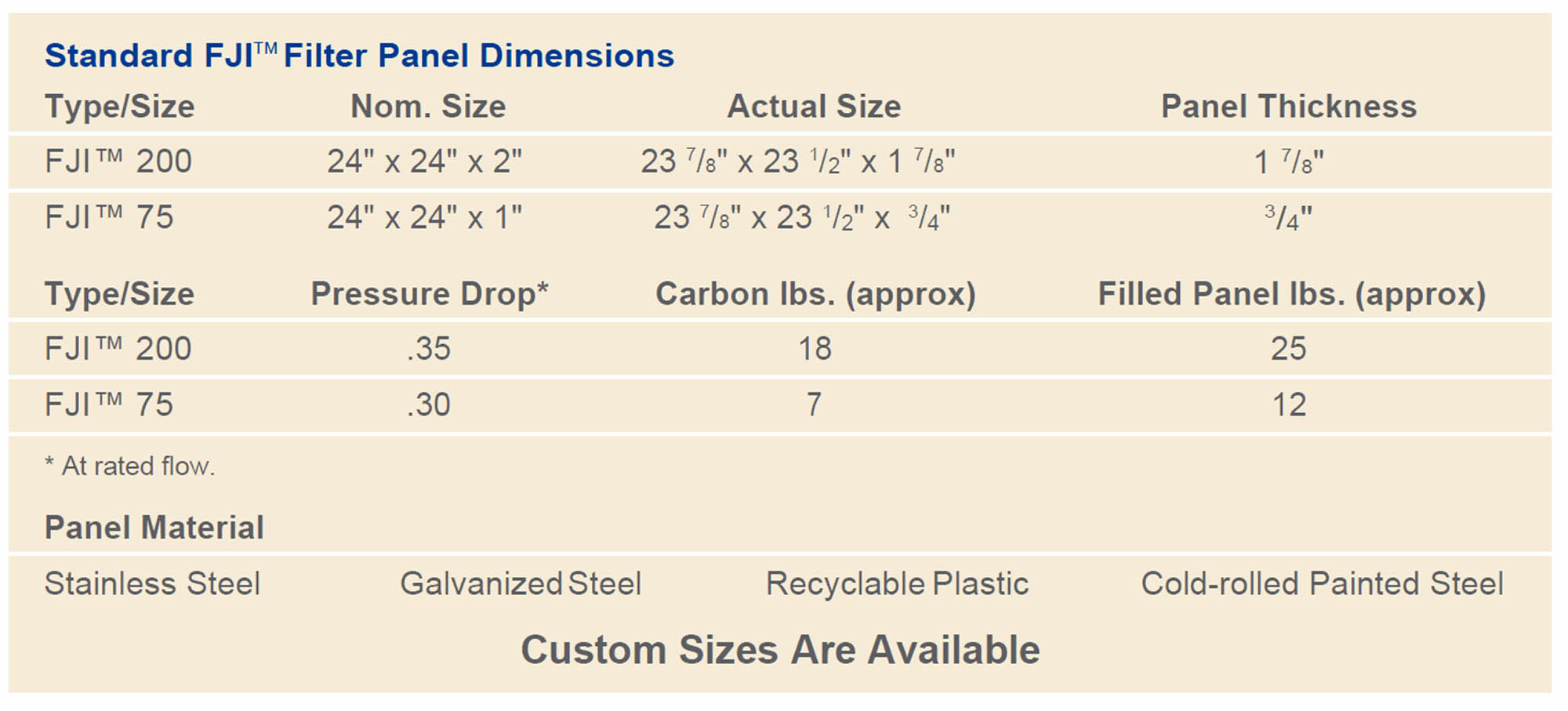

REFILLABLE CARBON PANELS

The FJI™ filter is an activated carbon, refillable panel typically used in our FLS™, FJS™, FLD™, or FJD™ housings. The panels can be packed with any of the more than 100 available activated carbon products offered by Continental Carbon Group, as well as with other media such as potassium permanganate. The panels are available in painted carbon steel, plastic, aluminized steel, or stainless steel construction. Standard size is 24” x 24” nominal with 1”, or 2” depths. Custom-sized carbon filter panels are also available based on customer need. CCG also offers a wide range of carbon panels in specific configurations that provide an alternative to the original equipment supplied and with a much larger range of media choices to meet your specific treatment objectives and achieve lower operation and maintenance costs.

Continental Carbon Group is constantly striving to improve its products and capabilities and to provide the best product to it customers. Continental Carbon Group may from time to time develop product improvements or alterations (including, without limitation, revisions to product specifications), and may implement such Product Improvements without notice to the Buyer.

Making Air Safer and Cleaner

SAFETY MESSAGE

Wet activated carbon removes oxygen from air, causing a severe hazard to workers inside carbon vessels. Confined space/low oxygen procedures should be put in place before any entry is made. Such procedures should comply with all applicable local, state and federal guidelines.